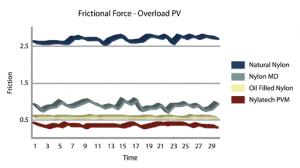

Of all the performance plastics to hit the market in recent years, perhaps none has created as much interest as Redco™ PVM nylon. PVM stands for “Pressure-Velocity-Maximum” and is a performance material designed for the most demanding applications. PVM has already proven itself as a replacement in kiln cart bushings. Traditionally, these bushings were made out of blue (high temperature) nylon; however, some sawmills on the U.S. Pacific Coast have been testing some PVM bushings in this application and so far the results are excellent. The bushings are not deforming and have already lasted four times longer than the blue.

Redco™ PVM can simply handle more pressure, more wear and more friction in most applications and can save money over its lifecycle while reducing maintenance downtime. For more information on Redco™ PVM nylon click here.