Urethane and rubber sometimes are lumped together as materials. This is because the two materials are both elastomers, meaning when compressed they will return to 90% of their original dimensions, though there is often 100% rebound in the rubber scale (shore A) urethanes. This elastomeric property means the materials can handle impact, shock and reduce vibration. However, while polyurethane is has a greater upfront cost-per-part, it will have superior properties and performance in equivalent applications. When the costs of downtime and the benefits of increased productivity and decreased maintenance are factored in – urethane’s lifecycle cost often proves to be lower. From bumpers to rollers to bushings and Deadplate™ – there is a urethane to solve virtually any mill need.

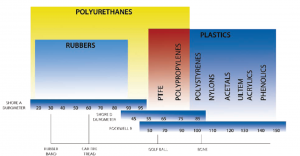

Polyurethanes are classified by the durometer scale. A higher number (approaching 100) refers to a harder material. Many urethanes fall into the “A” rubber scale; however, several do fall into the “D” or plastic part of the scale. See the scale in the picture below and click to expand it.

For more information on the grades of polyurethane available and specific applications, click here.