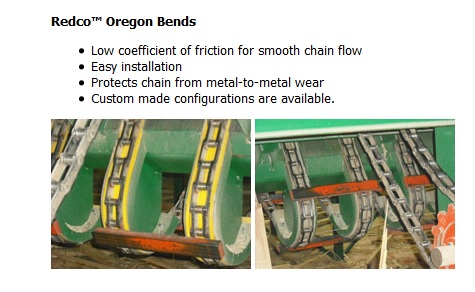

Oregon bends are segments of Redco chain channel that have been cut to a specified length and bent to a certain radius to go around equipment (see picture below). These bends are essential to allow the sawmill chain to return to the start of the table in a smooth and unbroken pattern. They can be affixed, by weld washers, same as the channel used for straight lengths. The manufacturing method used to make them is light thermoforming: the lengths of channel are heated to about 175 degrees where the UHMW plastic (which is what chain channel is made from) becomes quite soft and pliable. Our various branches have different methods to do this, but the end result is a bent channel that when cooled, will retain most of its shape.

We do need to be clear that a little “elbow grease” will be required to hold the oregon bends down during installation as there is unavoidable “rebound” after the bend cools. But this is not difficult to do. We can also supply these oregon bends out of both our regular clean/yellow/repro UHMW or our Redco Titanium channel. There is also the possibility that you can make your own oregon bends. A heat source like a BBQ would work well, just keep it on low. You will need some sort of mandrel, a circular drum-type object with the same diameter as your sawmill equipment. You simply bend the heated channel around that drum.

For information or a quote on UHMW oregon bends please contact Redwood Plastics.