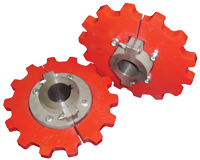

For customers who haven’t used plastic sprockets before, at first the product seems like a novelty. Many users think that the sprockets will be cheaper than metal because “it’s just plastic”. When they find out this isn’t true the question inevitably comes up “then why choose plastic sprockets?” It’s a good question and the answer is twofold. Firstly, and most important, is that plastic sprockets greatly reduce wear on the chain. One of the big reasons to put plastic in sawmills for any application is that when you mate a plastic to metal, the softer plastic wears substantially less. This saves money in the long run.

Secondly, metal on metal contact creates noise: a lot of noise. And sawmills are often under noise restrictions where noise must be kept below a certain level. The softer plastic when combined with the metal chain will help to reduce the noise output. This is further helped when combining sawmill chain with plastic chain channel. Other plastic parts in the sawmill such as diverter gates or arms and UHMW trimmer lugs function to do the same. As a bonus, high-quality industrial plastic lasts longer than an equivalent metal part – the plastic simply outwears the metal.

For a quote on Redco polyurethane sprockets please contact us today.