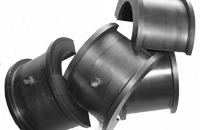

Plastics are excellent bushing material that replace metal. In contract to metal, plastic bearings are self-lubricating, require less grease or maintenance, and last longer. Typically six different plastic materials could be used as these bushings and each will be described.

Redco Polyurethane:

Called “Redco 750 XL” this is a lubrication impregnated polyurethane bearing material. It’s used where shock and vibration are special factors. It has the advantage of being able to be molded which means a low per-piece cost when purchased in bulk.

Redco Nylon:

The most common bearing material in a sawmill, nylon takes high pressure (4000 PSI) and is available in solid and liquid lubrication impregnated versions. High temperature formulas are also available.

Redco Acetal:

Perhaps the least common material used in sawmills, acetal replaces nylon in moisture-rich or submerged environments as nylon suffers from moisture absorption issues unlike most plastics.

Redco Phenolic:

Typically used under the highest load or highest heat applications.

Redco PTFE:

Used where extreme heat or extreme chemical exposure occurs but where a light duty (500 PSI or less) bearing material will suffice.

Redco UHMW:

No moisture absorption and is good for light load applications.

If you’re interested in more information or a quotation please contact Redwood Plastics and Rubber.