One question that keeps coming up regarding sawmill maintenance solutions is “Why can’t I glue it?” When discussing affixing the plastic solution, for example a wear strip, to a steel backing. The appeal of a glue or adhesive is that it’s easy to apply and would result in an unbroken part that does not require holes or hardware. However, there are many drawbacks to adhesives that mean mechanical fixation is always the best choice whenever available.

What are the problems with adhesives?

- Different plastics bond with different strength even with the same adhesive

- Some plastics cannot be bonded at all

- An adhesive bond is weaker than mechanical fixation

- Adhesives can be attacked by chemicals or moisture saturation

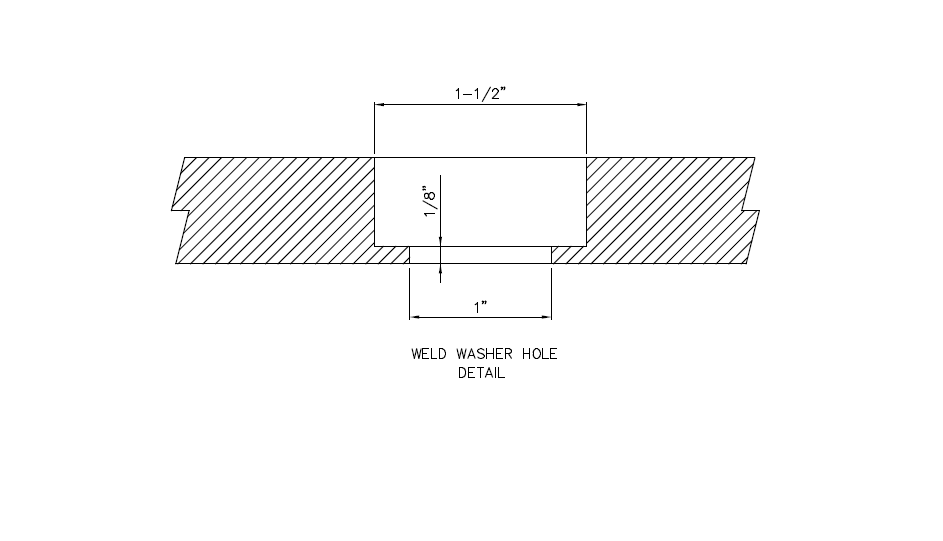

The benefits of mechanical fixation (weld washers, bolts, or screws) is that the bond will be long-lasting. Even if the fasteners, which are whole or in part metal, start to corrode that will occur slowly and be noticed. It’s very likely the part will need replacement before the fasteners do. Plastic fabricators such as Redwood Plastics and Rubber are familiar with mechanical fasteners, especially weld washers, and carry thousands of weld washers in stock. Redwood Plastics and Rubber can provide advice on on hole patterns for weld washers or just let us supply the parts complete with holes and fasteners.